No products in the cart.

March 13, 2025

Become a valued dealer! Share your details below to get access to our wide range of high-quality products and grow your business with reliable support from RCBearings.

Become a valued dealer! Share your details below to get access to our wide range of high-quality products and grow your business with reliable support from RCBearings.

When we think about powerful engines, most of us imagine pistons, crankshafts, or valves working in harmony. But hidden inside every high-performing engine lies a small yet critical part—the engine bearing. Without it, your engine simply cannot run efficiently. Bearings reduce friction, support rotating parts, and ensure long-lasting performance. In this guide, we’ll dive deep into what engine bearings are, why they matter, the different types, common problems, and how to extend their lifespan.

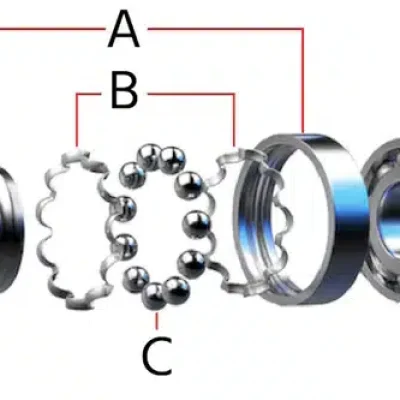

At their core, engine bearings are precision-engineered metal or alloy components that allow smooth rotation between engine parts. They sit between moving components—like the crankshaft and connecting rods—acting as a protective layer.

Imagine running your hand across a rough surface versus a smooth one. Bearings provide that “smooth surface,” preventing direct metal-to-metal contact, which would otherwise cause rapid wear, heat buildup, and eventual failure.

Key functions of engine bearings include:

Supporting the crankshaft and connecting rods under immense loads

Reducing friction for smoother movement

Absorbing shock and vibration from combustion forces

Distributing oil flow to keep engine parts lubricated

In short, without bearings, an engine would seize up within minutes.

The health of your bearings directly impacts engine performance, fuel efficiency, and lifespan. Since they reduce friction and wear, bearings make it possible for engines to run at high speeds without overheating or breaking down.

Here’s why they matter:

Performance: Bearings keep parts aligned and moving freely, maximizing efficiency.

Longevity: By minimizing wear, they extend the overall lifespan of the engine.

Reliability: Bearings reduce the risk of breakdowns, saving you from expensive repairs.

Smooth Operation: They absorb shocks, making engines quieter and smoother to drive.

Think of them as the “hidden heroes” working tirelessly every second your engine runs.

Despite their durability, engine bearings are not invincible. Over time, they face wear and damage due to extreme operating conditions.

Common causes of bearing failure include:

Oil Starvation – Lack of lubrication leads to friction and overheating.

Contamination – Dust, dirt, or metal debris scratches bearing surfaces.

Overloading – Aggressive driving or towing heavy loads strains the bearings.

Overheating – High temperatures cause metal fatigue and warping.

Misalignment – Poor installation or stress can cause uneven wear.

Warning signs to watch for:

Engine knocking or rumbling noises

Low oil pressure readings

Metal shavings in engine oil

Vibrations during acceleration

Catching these early signs can prevent costly damage like a seized engine or crankshaft replacement.

The good news? With proper care, engine bearings can last the entire life of your engine. Here are proven tips to maximize their durability:

Use high-quality engine oil: Stick to manufacturer-recommended oils with the right viscosity.

Change oil and filters regularly: Prevents contamination and ensures clean lubrication.

Avoid sudden stress: Aggressive acceleration, racing, or towing puts unnecessary strain on bearings.

Monitor oil pressure: Low oil pressure can indicate bearing wear or lubrication issues.

Stick to scheduled maintenance: Regular check-ups can spot problems before they escalate.

By following these steps, you protect not just your bearings but your entire engine’s health.

hough small in size, engine bearings are vital for smooth, efficient, and long-lasting engine performance. They’re the silent guardians that keep your crankshaft, pistons, and camshaft working in perfect harmony. By understanding their role, recognizing early warning signs, and committing to regular maintenance, you can extend engine life and avoid costly repairs.

RCBearing provide high-precision, high-quality anti-friction Bearings with exclusive range.

© 2025 RCBearing . All Rights Reserved.