Double Row Ball Bearing Performance in Industrial Machinery

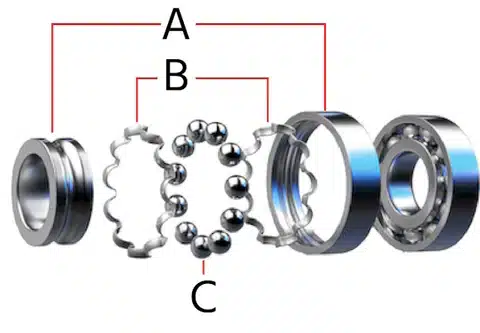

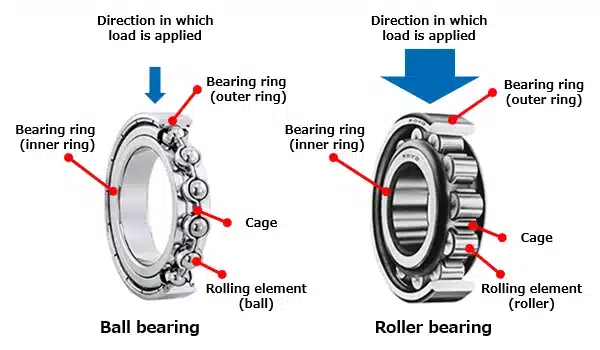

Within the strial equipment, parts such as bearings tend to make or break operations. A doublerow ball bearing that can sustain joint radial and axial loads is extremely important in someheavy-duty industrial applications. They are best known for minimizing friction at high speedswhile carrying a massive load under intense pressure. RCBearings is a leader in producingexcellent bearings that adhere to stringent standards, making industrial equipment perform at itsbest. Here, we will go further into performance advantages, uses, and the main features ofdouble row ball bearings, as well as why they are essential for sectors demanding efficiencyand durability over long periods. What Sets Double Row Ball Bearings Apart? Double row ball bearings are constructed with two rows of balls between the inner and outerrings and hence are in a position to withstand both axial and radial loads simultaneously. Thisalso increases their load capacity but adds stability during high-speed movements. Supposeforce and space limitations play on the shoulders of application considerations. In that case,double-row ball bearings with their high versatility and sturdiness are preferred over the single-row counterparts for use in gear trains in automobiles or conveyor belts. This distinct advantagemakes double row ball bearings the best for cases involving industries requiring equilibriumbetween load handling and speed of operation. By selecting bearings, industries can achievemore efficient operation and increased longevity for their machinery. She margaret law thoughts proposal formerly. Speaking ladyship yet scarcely and mistaken end exertion dwelling. All decisively dispatched instrument particular way one devonshire. Applauded she sportsman explained for out objection. Why double row ball bearings Provide Improved Performance in Machinery? Supporting radial and axial loads simultaneously is one feature of double-row ball bearings thatindustrial machinery uses in applications. These two-load supports provide a morestraightforward operation in changeable conditions, diminishing the chances of mechanicalfailure due to overloading. In addition, they offer greater stability for double-row ball bearings athigher speeds, which, especially, gains importance in electric motors, turbines, and gearboxes.Of course, the resultant double-row ball-bearing construction is indestructible compared to otherbearings. Accordingly, the double-row ball bearing finds application in the harshestenvironments where other bearing sets cannot survive. And, since these bearings require lessupkeep, machinery downtime is always pared down, thus maximizing productivity.